We all know what elevators or lifts are! Elevators make our work easier. When you are in the elevator, it even feels like you are flying from down to up. They are small in size but occupy a handful of people and can help them reach from one destination to another.

Builders discovered this method while constructing buildings. If they wanted to travel from the lower floor to the higher floor, the builders used a machine that carries the raw materials used to construct floors like cement, bricks, sand, etc. As this method developed, the lift was invented.

Other manufacturing products lead to difficulties while installing. So, the machine room less elevators system was developed. It is safe to hoist the motors. Manufacturers of machine room less elevators designed the system that incorporates overhead structures and uses it as a rigging point in the hoistway.

Installation of the MRL Lift Machines

The installation process is done by building an overhead structure; first, that’s an all-structural steel system that attaches at the top of the hoistway. The essential parts of the system are the horizontal channels that mount to the wall on each side of the hoistway, and once those are mounted, the vertical channels are attached to the horizontal channels.

Finally, install your overhead support tube, which allows the equipment to be brought into the hoistway and lifted into position safe bedplate quickly.

The system is designed in a way so that you can install the machine template and the machine safely and efficiently at the top of the shaft. It would help if you safely hoisted the machine up onto the bedplate using the trolley system and hoist. Then install the single rail hitch plate, which is then completed MRL support frame machine plate and single rail hitch plate.

When should you choose MRL (Machine Room Less Elevators) lift machines?

Let me give you a small Intro to the latest model machine room less elevators system and list some of the innovative designs that the manufacturers had corporated into the system.

The rail bracket assembly has very innovative features that make installation quick and easy. The rail bracket assembly features a precisely aligned system at the factory welded together, so there is not much adjustment required in the field. The distance between guides for the counterweight is preset, and the attachment points for the main guide rail.

The main guide rail attaches threaded holes that allow the rails to be installed quickly and accurately indexed to the opposite guide rail. The whole system is designed to be installed in the most efficient way possible by your field personnel so that your elevators get done on time with a work platform. You can install an MRL machine in less than a day. These lifts are gearless.

The regulations of machine room less elevators in India and other lifts include the following,

● In India, the builders or constructors need to comply with specific regulations to install and use lifts.

● From low rise to high rise, building lift has an integral part and more than an amenity. So due to this increasing use and demands of buildings, it is essential to understand the living being’s lift regulations and safety security.

● The lift regulates the safe working of MRL lift Machines India and construction maintenance conducts and restrictions made in specific states.

● The Indian principles of machine room less elevators also specify how to conserve the welfare for safety, consider how to install the elevator, and operate and ensure the safety of the passengers.

How does MRL look, and how does it work?

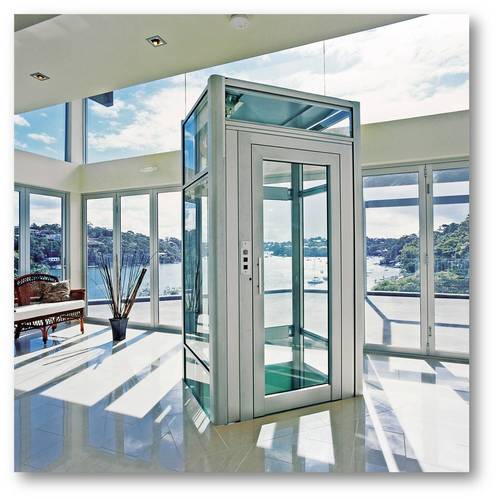

Let us have a look at the beautiful glass lift, which is a cube ultra bed MRL. It’s the Machine Room’s best lift. Few buildings will not have the provision to install a lift, so quality manufacturers fabricate their shafts to create the lift. MRL lifts are fully automatic with big vision glass, main windows.

Machine release because there is no lift machine room that is separate. All the equipment is inside the lift well, with the lift controller being in the door jamb of the top floor.

The main circuit board or microprocessor that technicians access to undergo diagnostics. In addition, a brake release device would be used in the event of a power failure to roll the lift and then at the other end of the maintenance operation. It also contains several circuit breakers and relays.

Machine room less elevators being a machine reverse lift – The gearless machine, the drive, and other components are all in the lift itself.

It has a Gillis hoisting machine, and there is a break on either side of the hoisting machine. The machines are mounted on the car rails which the car drives on the hoisting ropes.

The main drive and there will be standing ends of the hoisting ropes at the opposite side. This MRL lift is a ride 2 to 1, which means a sheave on top of the counterweight.

Why should you choose MRL lift machines?

Other lifts require a machine room at the top of the lift, also known as a lift room. In contrast, you will not require a machine room at the top of the lift in MRL lift machines.

The overhead in MRL and other lifts remain the same. The height of the lift room can be 7 feet approximately. So, while you choose machine room less elevators, your space or area is also not wasted. It is compact and straightforward to install. It is not necessary to hold a vast area to install MRL lifts.

Advantage of MRL lifts

● It can save more space in your buildings.

● Since it saves more space which means the cost to install the lift also will be less.

Conclusion

From the above explanation, we can easily understand that MRL lift machines India might not be comfortable, but it is simple and easy to install compared to other lifts. It saves your time, space, and money. So, Machine Room Less lift is a good option!